Flue gas desulfurization engineering

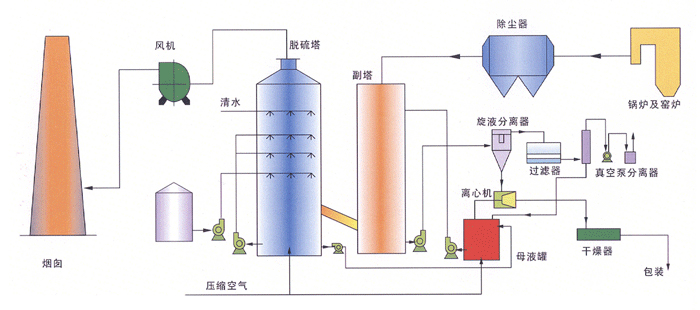

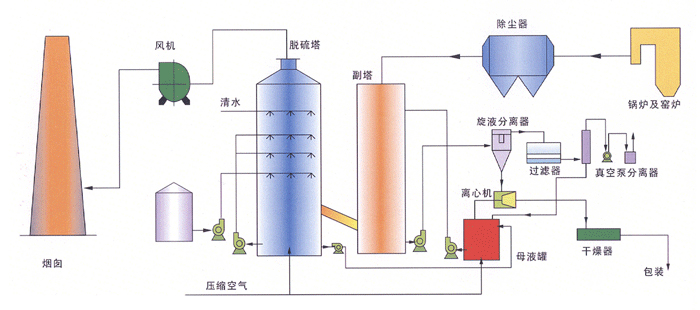

Flow chart

Flue gas desulfurization engineering refers to the removal of sulfur oxides (SO2 and SO3) from flue gas or other industrial waste gases.

Characteristics of limestone-gypsum flue gas desulfurization system

The system availability exceeds 99%;

Can operate at high flue gas flow rate, optimized absorber size, absorber liquid redistribution (ALRD) patented technology improves gas-liquid ratio (L/G);

A high-speed mist eliminator can be used, and a cyclone can be used to promote the recycling of calcium carbonate;

High desulfurization efficiency (limestone>98%, high-magnesium lime>99%), low energy consumption;

Load adaptability is large.

Wet ammonia-ammonium sulfate recovery method desulfurization is a new flue gas desulfurization technology, which has high desulfurization efficiency and no secondary pollution. Ammonium sulfate, the by-product of desulfurization, conforms to the national agricultural chemical fertilizer standard, and truly realizes the transformation of harm into profit and waste into treasure, with economic, social and environmental benefits.

Technical Features

1. It has a wide range of applications and is not limited by the sulfur content of coal combustion and boiler capacity;

2. The desulfurization efficiency is very high, which can easily reach more than 98%. The flue gas after desulfurization not only has a very low concentration of sulfur dioxide, but also greatly reduces the dust content of the flue gas;

3. The absorbent is easy to purchase and can be in three forms: liquid ammonia, ammonia water, and ammonium bicarbonate;

4. Low operating cost and high value of desulfurization by-products;

5. Complete resource utilization - turning waste into treasure and harm into profit.